Moved by news coverage of the impact coronavirus has had on the medical community, a semi-retired inventor from Arizona had an audacious idea: to create an open-source ventilator made from off-the-shelf industrial parts. Luther Johnson’s thinking was that with the sudden shortage of ventilators, his project could act as a fast stopgap that medical facilities could make themselves. Johnson dubbed the project MakerVent and set about sourcing parts for the first build.

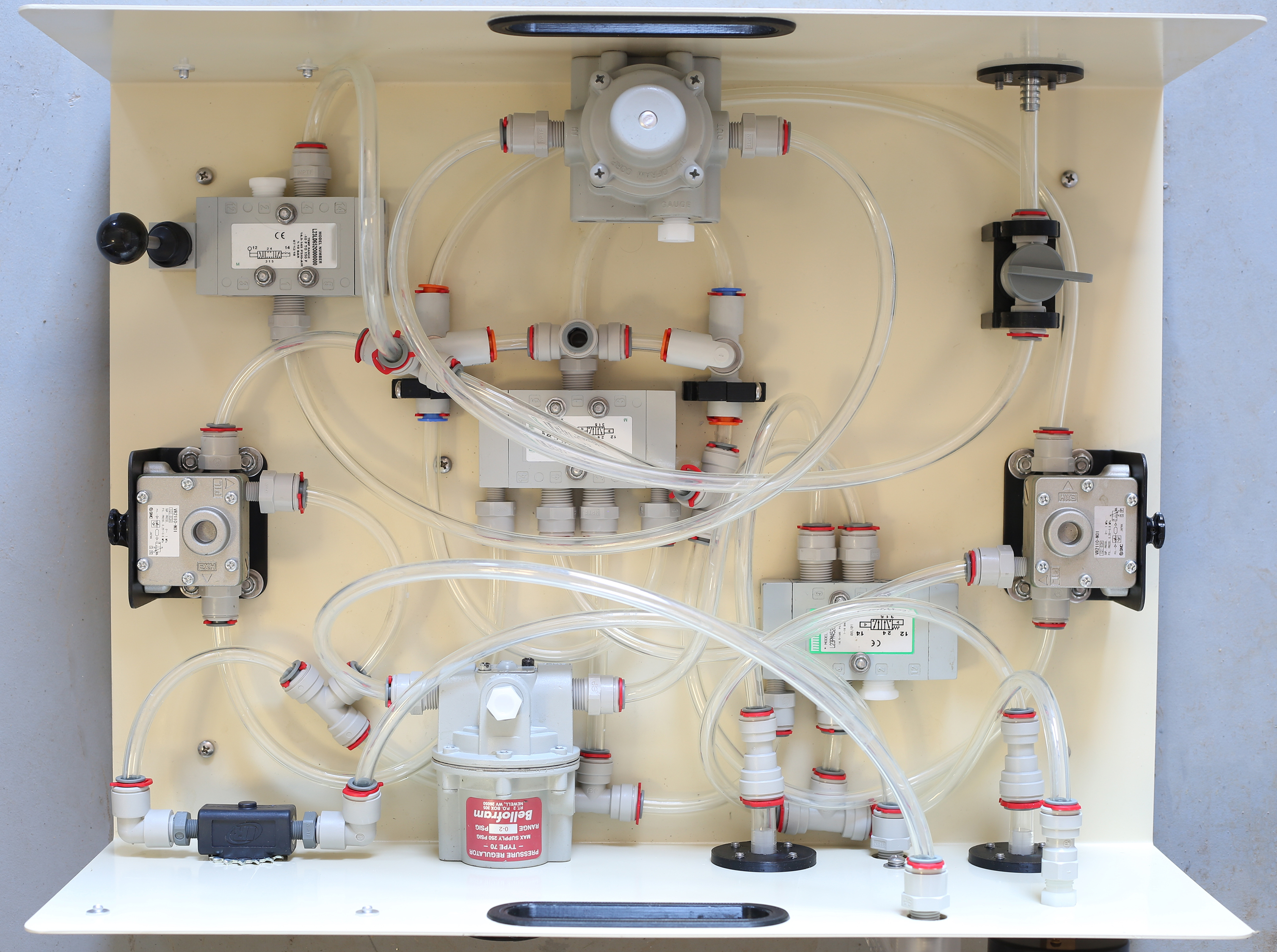

That’s what led him to Bellofram Precision Controls, a division of Marsh Bellofram. After a deep dive into ventilator research, Johnson based his design on a fully pneumatic, electricity-free ventilator dating from the 1970s. He used two kinds of Bellofram gas pressure regulators for the important job of controlling the flow of oxygen through his ventilator.

The first is Bellofram’s Type 60 Preset General Purpose Air Regulator, which receives the initial oxygen input, typically provided from a hospital’s wall unit or a tank, and reduces the pressure to 30 psi. The second Bellofram piece is the Type 70 High Flow Pressure Regulator. It is located at the opposite end of the process, just before the oxygen reaches the patient, and further regulates the air flow to less than 1 psi, a safe pressure for human lungs.

Johnson reviewed all parts used in the device for biocompatibility, and each is also subjected to a special oxygen cleaning protocol. This process removes dust, oils, and residue native to industrial manufacturing and renders the parts safe for human use. In a testament to the effectiveness of these protocols, the first production unit of the MakerVent ventilator recently passed ISO 18562 compliance testing at a national lab, meaning it is safe to deliver breathable gas.

In addition to benefiting from Bellofram’s reliable products and its own ISO compliance, Johnson also appreciates the support he received from the company’s applications engineer, Jeff Wetherell. “Jeff has been a trusted source for me throughout this process,” said Johnson. “His recommendations and assistance with these regulators were a big part of why I had confidence that these were the right parts for this project.”

There’s an appetite in the market for Johnson’s machine. A U.K.-based physician has already built his own MakerVent and is assisting Johnson with development. Now that the device has cleared ISO testing, Johnson hopes to get it in front of the FDA for approval.

“I understand that MakerVent won’t be the right fit for every situation that calls for a ventilator,” said Johnson. “But in these challenging times, I believe it’s important to do something, to keep moving forward, and I hope MakerVent can help.”

To learn more about Bellofram Precision Controls, visit http://mb-precisioncontrols.com/.

To learn more about MakerVent, visit https://www.makervent.com/.

About The Marsh Bellofram Group of Companies

Headquartered in Newell, W. Va., USA, The Marsh Bellofram Group of Companies is an AS9100D and ISO9001:2015 certified global manufacturing collective. Its portfolio comprises high-performance OEM, industrial, and process control instrumentation, including timers and counters, digital controllers, RTDs and thermocouples, pressure instruments and gauges, FRLs, cylinders, natural gas and propane pressure regulators, valves, air pressure regulators and transducers, tank and liquid level measurement systems, pump and motor protection switches and alternating relays, as well as sensors, DC tachometers, encoders, industrial diaphragms, and specialty silicones. For more information, visit www.marshbellofram.com.

###